## Hold onto your wallets, gamers, because your next iPhone might cost you a small fortune!

Imagine shelling out $3,500 for a brand new iPhone, a price tag that could rival a mid-range gaming PC. Sounds crazy, right? Well, a Wall Street analyst says it’s a real possibility if Apple decides to bring its iPhone production back to the USA.

The Impact on Consumers: A Potential Price Tag of $3,500 for a Domestic iPhone

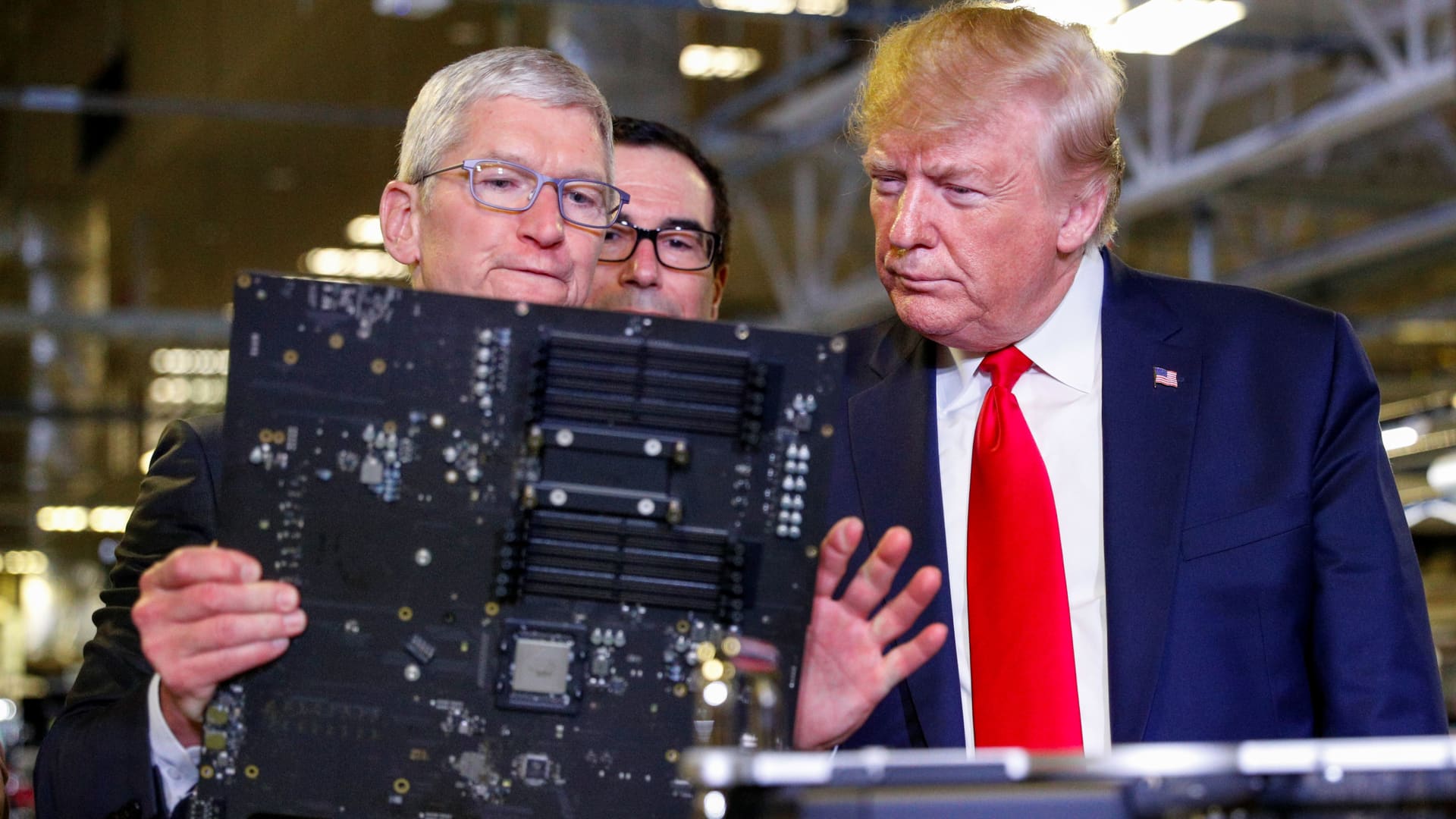

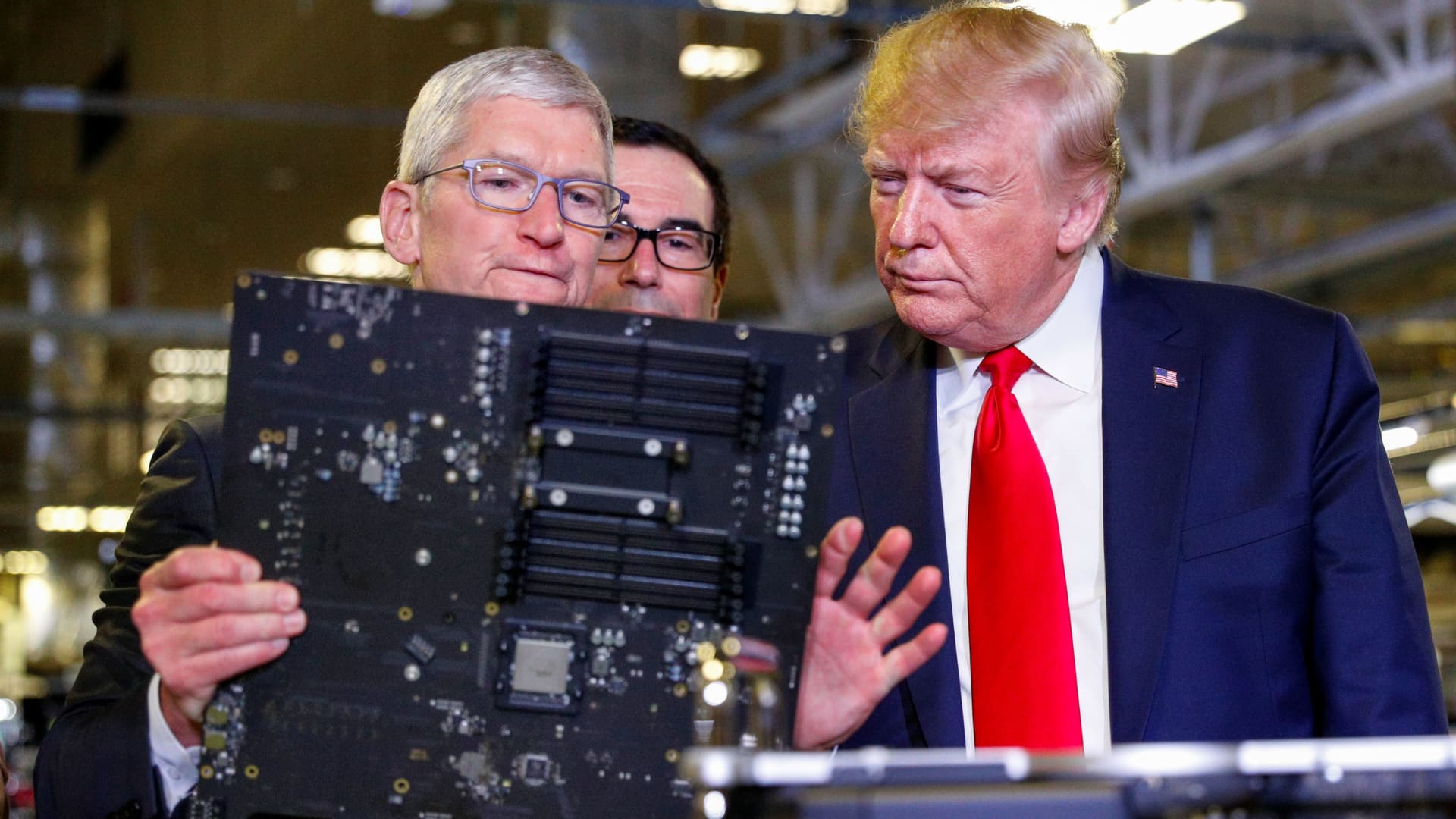

The prospect of a “Made in USA” iPhone has sent ripples through the tech industry, raising questions about the potential impact on consumers. If President Trump’s threat of a 25% tariff on iPhones manufactured outside the US comes to fruition, Apple would face immense pressure to increase prices to offset the added costs. Analysts predict a significant price hike, with some even suggesting a staggering $3,500 price tag for a domestically produced iPhone.

This drastic increase in cost would undoubtedly affect consumer behavior. Gamers, in particular, who rely on iPhones for mobile gaming, could face a significant financial hurdle. The accessibility of high-end technology would be considerably reduced, potentially limiting the market for innovative mobile games and accessories.

The Reality Check: Why a US-Made iPhone Might Not Happen

Although the idea of a “Made in USA” iPhone has gained traction in recent discussions, several factors make it a highly unlikely scenario in the near future.

The Lack of a Skilled Workforce

A major obstacle to US iPhone production lies in the availability of a skilled workforce capable of handling the complex assembly and manufacturing processes. The US manufacturing sector has experienced significant decline over the past few decades, leading to a shortage of workers with the necessary expertise. Re-training a large number of workers to meet the demands of iPhone production would be a lengthy and costly endeavor.

Apple’s Globalized Supply Chain

Apple’s supply chain is a meticulously orchestrated network of international partnerships and dependencies. Shifting production to the US would require significant logistical adjustments and renegotiations with numerous suppliers and manufacturers. The company relies heavily on economies of scale and specialized expertise found in countries like China, making a complete shift in production a daunting task.

The Unpredictability of US Trade Policy

The current political climate surrounding trade policy adds an element of uncertainty to any long-term investment in US manufacturing. The threat of tariffs and trade wars poses a significant risk for manufacturers, making it difficult to plan and commit to large-scale production shifts.

Beyond the Headlines: What This Means for Gamers and Tech Enthusiasts

The potential for a “Made in USA” iPhone has far-reaching implications for gamers and tech enthusiasts.

Potential Delays and Shortages

A shift in iPhone production could disrupt the global supply chain, leading to potential delays in the release of new iPhones and gaming accessories. Gamers who rely on the latest iPhone models for optimal mobile gaming experiences could face frustration and uncertainty. Shortages of critical components could further exacerbate these issues, impacting the availability of both iPhones and related gaming peripherals.

The Future of US Manufacturing

The decision to manufacture iPhones in the US could signal a broader trend of reshoring manufacturing operations. This could potentially revitalize the American manufacturing sector and create new job opportunities. For gamers, it could mean a resurgence of locally produced gaming hardware and accessories, fostering a more vibrant and localized gaming ecosystem.

The Value of Innovation

The pursuit of a “Made in USA” iPhone could incentivize Apple to invest in new technologies and manufacturing processes. This could lead to advancements in areas like robotics, automation, and sustainable manufacturing practices. Gamers could potentially benefit from these innovations through more powerful, efficient, and environmentally friendly gaming devices.

Conclusion

The Shocking Truth Behind a Made-in-USA iPhone

In our recent article, we delved into the eye-opening claims made by a Wall Street analyst, who suggested that a made-in-USA iPhone could come with a hefty price tag of $3,500. The analyst’s argument centered around the fact that a significant portion of the iPhone’s cost is comprised of components sourced from countries like China and Vietnam, where labor costs are relatively low. If Apple were to manufacture the iPhone entirely in the United States, the increased labor costs and logistical expenses would inevitably translate to a higher price point for consumers. Additionally, the article highlighted the complexities of the global supply chain and the challenges that Apple would face in attempting to shift its manufacturing operations to the US.

The implications of this analysis are far-reaching and significant. If a made-in-USA iPhone were to hit the market with a price tag of $3,500, it would not only be a shock to consumers but also a major blow to Apple’s market share. The company has already been facing intense competition from Chinese smartphone manufacturers, and a drastic price hike could further erode its customer base. Furthermore, the article raises important questions about the feasibility and desirability of American manufacturing, particularly in the context of the tech industry.

As we look to the future, it’s clear that the debate around American manufacturing and its impact on consumer prices will only continue to intensify. Will Apple be able to find ways to mitigate the costs associated with domestic manufacturing, or will the company be forced to adopt more cost-effective strategies? One thing is certain: the future of the iPhone and the global tech industry hangs in the balance. The question is, can Apple afford to make the iPhone in America? Only time will tell.