## Gamer, Are You Ready to Power Up Your Future with Water?

Forget mana potions and energy drinks, the future of powering your gaming sessions might just be, well, water. H2Pro, a company dedicated to revolutionizing the way we generate clean energy, has developed a groundbreaking technology called “Decoupled Water Electrolysis.” Think of it like a supercharged, ultra-efficient water splitter, turning plain ol’ H2O into hydrogen fuel – the green energy source that could one day fuel our cars, homes, and yes, even our gaming rigs.

Key Components and Their Function: A Closer Look at the System Architecture

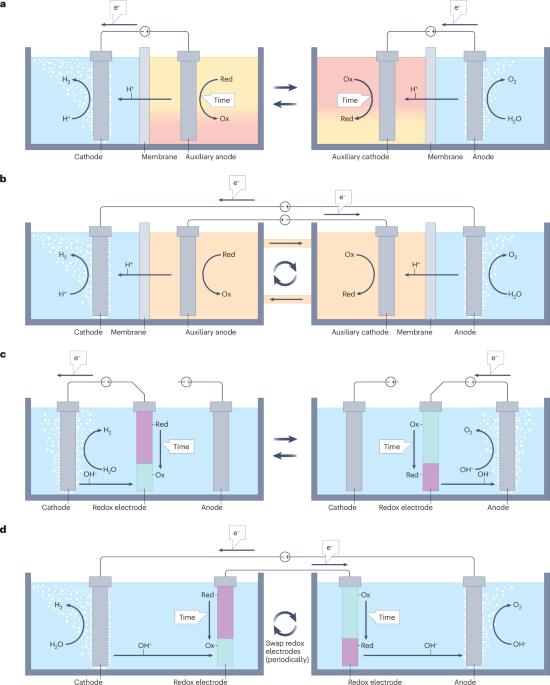

H2Pro’s decoupled water electrolysis technology operates on a distinct principle compared to traditional methods. At its core lies a system that separates the electrochemical reactions of hydrogen and oxygen evolution. This separation is achieved through a unique architecture comprising several key components:

- Electrodes: The system employs two sets of electrodes, specialized for each reaction. One set facilitates the hydrogen evolution reaction (HER), while the other drives the oxygen evolution reaction (OER). These electrodes are typically made of highly conductive materials like platinum or alloys, chosen for their catalytic properties.

- Electrolytes: H2Pro utilizes electrolytes tailored for each electrode compartment. These electrolytes facilitate the transport of ions, playing a crucial role in maintaining the electrochemical equilibrium within the system.

- Electrolyte Separator: A specialized membrane or separator physically isolates the two electrode compartments. This prevents the mixing of the electrolytes, ensuring that the hydrogen and oxygen production reactions occur independently.

- Redox Mediator: A key innovation in H2Pro’s technology is the use of a redox mediator. This soluble molecule shuttles electrons between the electrodes, enabling the decoupling of the HER and OER processes. The mediator is regenerated at the respective electrodes, facilitating a continuous flow of electrons and ions.

- Improved Overpotential: By separating the HER and OER, H2Pro’s system can operate at lower overpotentials, the additional voltage required beyond the theoretical thermodynamic limit. This reduction in overpotential translates to lower energy consumption and increased efficiency.

- Higher Current Density: H2Pro’s technology allows for higher current densities, meaning that more hydrogen can be produced per unit area of electrode. This density increase further enhances the system’s energy output and overall productivity.

- Enhanced Durability: The decoupled nature of the reactions reduces the risk of unwanted side reactions and electrode degradation, leading to improved system durability and longevity.

- Controlled Environment: H2Pro’s systems are designed to operate in a controlled environment, minimizing the risk of accidental ignition or leaks.

- Leak Detection and Prevention: Robust leak detection systems are integrated into the design to identify and address any potential hydrogen leaks promptly.

- Explosion-Proof Components: Critical components are engineered to withstand potential explosions, minimizing the risk of damage and ensuring the safety of personnel and surrounding infrastructure.

- Redundancy Systems: H2Pro incorporates redundancy in key systems, such as power supply and control systems, to ensure continued operation even in the event of component failure. This redundancy provides an additional layer of safety and mitigates potential hazards.

The interplay of these components enables the efficient and controlled production of hydrogen and oxygen. The separation of the reactions enhances the system’s overall performance and paves the way for improved energy efficiency.

Enhanced Efficiency and Durability: Analyzing the Performance Benefits

H2Pro’s decoupled water electrolysis technology presents several performance advantages over conventional methods:

These performance benefits stem from the fundamental design principles of H2Pro’s approach. The separation of the electrochemical reactions allows for optimization of each individual process, resulting in a more efficient and durable system. This translates to significant cost savings and increased sustainability in the long run.

Addressing Safety Concerns: Examining the Mitigation Strategies for Hydrogen Production

Hydrogen, being highly flammable and explosive, requires careful handling and safety considerations during its production. H2Pro acknowledges these concerns and incorporates several mitigation strategies to ensure safe operation:

By adhering to strict safety protocols and employing advanced mitigation strategies, H2Pro aims to ensure the safe and responsible production of hydrogen, minimizing the risks associated with this flammable gas.

Implications and Applications: Shaping a Sustainable Future

H2Pro’s decoupled water electrolysis technology holds immense potential for revolutionizing various sectors and contributing to a more sustainable future:

Revolutionizing Energy Storage

H2Pro’s technology provides a promising solution for renewable energy storage. Excess electricity generated from sources like solar and wind power can be used to produce hydrogen, which can be stored and later utilized as a clean energy source. This storage capability addresses the intermittency challenge associated with renewable energy, ensuring a reliable and consistent energy supply.

Decarbonizing Industries

Hydrogen can serve as a clean and versatile fuel in various industrial processes. H2Pro’s technology enables the production of low-carbon hydrogen, which can be used to decarbonize sectors like transportation, manufacturing, and power generation. Replacing fossil fuels with hydrogen in these applications significantly reduces greenhouse gas emissions, mitigating climate change.

Environmental Impact: Assessing the Sustainability and Scalability of H2Pro’s Approach

H2Pro’s decoupled water electrolysis technology offers several environmental advantages:

- Low Carbon Footprint: The process primarily relies on renewable electricity, resulting in minimal greenhouse gas emissions during hydrogen production. This aligns with the global efforts to reduce carbon emissions and transition to a low-carbon economy.

- Water Conservation: Water consumption is a crucial consideration in hydrogen production. H2Pro’s technology utilizes water efficiently, minimizing the environmental impact associated with water usage.

- Scalability: H2Pro’s approach is scalable, allowing for the production of hydrogen on a large scale to meet the growing global demand. This scalability is essential for widespread adoption and the transition to a hydrogen-based economy.

Looking Ahead: The Future of Decoupled Water Electrolysis

H2Pro’s decoupled water electrolysis technology is poised to play a pivotal role in shaping the future of clean energy:

Market Potential and Growth

The global hydrogen market is expected to witness significant growth in the coming years, driven by increasing demand for clean energy solutions. H2Pro’s technology is well-positioned to capitalize on this growth, offering a competitive and sustainable solution for hydrogen production. The company’s focus on innovation and efficiency will likely attract significant investment and market share.

Research and Development

H2Pro continues to invest in research and development to further enhance its technology. Ongoing efforts focus on improving efficiency, reducing costs, and exploring new applications for decoupled water electrolysis. These advancements will solidify H2Pro’s position as a leader in the hydrogen industry and drive innovation in clean energy solutions.

Collaboration and Partnerships

Building a sustainable hydrogen ecosystem requires collaboration and partnerships. H2Pro actively engages with industry partners, research institutions, and policymakers to foster innovation and accelerate the adoption of its technology. These collaborations will leverage collective expertise and resources to overcome challenges and unlock the full potential of hydrogen as a clean energy carrier.

Conclusion

H2Pro’s Decoupled Water Electrolysis Technology is a game-changer, folks. We’ve seen how it breaks the mold of traditional electrolysis, achieving efficiency and practicality that were once considered pipe dreams. By separating the crucial components of the process, H2Pro has unlocked a level of control that allows for faster reaction times, reduced energy consumption, and the potential to utilize renewable energy sources more effectively. This isn’t just about efficient green hydrogen production; it’s about rewriting the rules of the energy future. Imagine a world where clean fuel is readily available, powering everything from our homes to our vehicles, all while combating climate change. This technology brings us closer to that vision, offering a sustainable and scalable solution to a global challenge. As H2Pro refines and expands its technology, we can expect to see a ripple effect across industries, driving innovation and pushing the boundaries of what’s possible. The future of energy is decoupled, and it’s looking brighter than ever.